"There is no better way to know your material than to go directly to the source." - Nini Hu, Founder of &HER

We use 3 fibers in each &HER bra: Cotton, Roica, Tencel. We kept it simple because that is all you need. The best cotton we can source, the most sustainable spandex that is available, and the cellulosic fiber that help to stabilize the Roica during knitting. Most of the &HER bras have 86% cotton in the content, so it is important for us to know about the crop, and there is no better way to know more than go directly to the source.

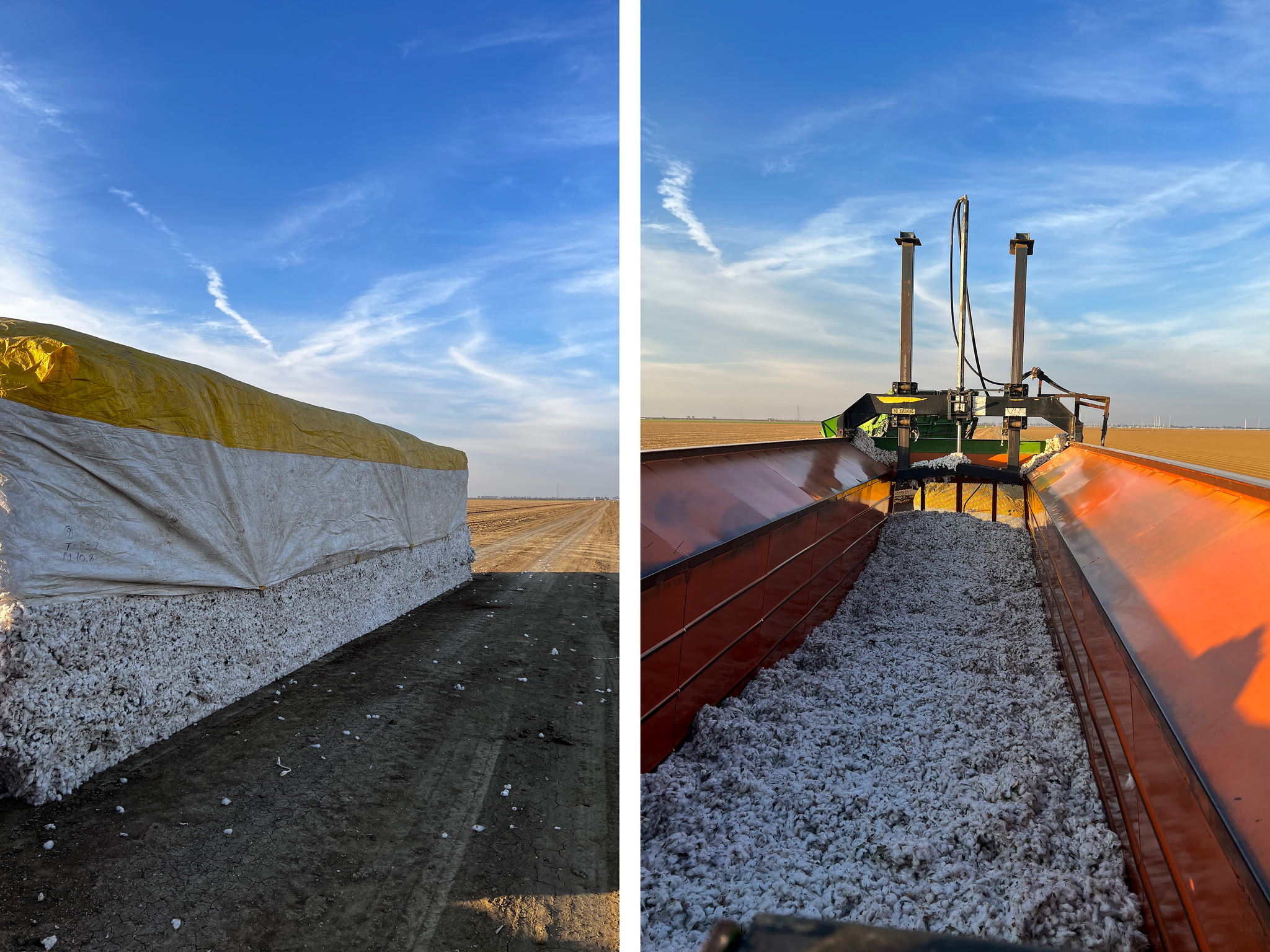

Supima Cotton Field in a November Afternoon

We were impressed by the farm's commitment in using state-of-the-art technology and other advanced farming practices to monitor soil health and improve efficiency. Ted's farm deploys satellite imaging to survey crops from above and wireless oil moisture sensors to gauge water usage. The farm has adopted drip water system and increased crop production with less water. Soil health, efficiency, and sustainability are not just "in-fashion" concepts, but a long and serious pursuit that is at the root of each farmer's livelihood.

Supima cotton crop packed and resting in the field. Ready for Gin.

Kirk Gilkey's Cross Creek Gin is located in Cocoron, CA. This gin facility is only operational during the cotton harvest season in the fall. It is powered by solar panels and is a zero waste facility. In the ginning process, cotton is transported through a series of mechanical cleaning steps where debris such as plant stalks, stems, and leaves are removed along with the seeds. The cotton lint is then bales, tagged and labeled. The waste from the gin process becomes feed for the nearby cattle ranch or compost to replenished the farm land.

Cotton (with dirt, branches, leaves, and seeds) ready for gin.

Separating cotton from debris in slow motion

Separating cotton from debris in slow motion

Separating cotton from debris in slow motion

Cotton bale ready. Samples were sent to the USDA cotton office for grading.

Trash from the cotton gin process. Waste will become feed for cattle ranch or compost for farmland.

USDA cotton programs are sponsored by the gin facilities. It grades cotton and classifies based on fiber length, uniformity, strength, and micronaire. It used to be a manually process with a specialist hand pulling the lint apart and making a visual judgement. Today, every sample goes into an instrument to be measured with previse data.

Inside the USDA cotton program office.

Based on the quality, the cotton bales will enter the market and be sold based on the prices warranted from its grade. Each year, less than 1% of the world's cotton is Supima, and the production continues to wane.